Introduction

Toothed steel grating is made of welded flat steel and twisted steel with a serrated side. In addition to all the characteristics and uses of ordinary steel grating, it also has strong anti-skid ability. It is especially suitable for stairs, wet and slippery occasions. Places in the north that have been covered with ice and snow for a long time and offshore oil production platforms, etc. The serrated steel grating adopts hot-dip galvanized surface treatment, which has strong anti-corrosion ability. Generally, when the installation slope of steel grating is greater than 10°, it should be made of anti-slip flat steel.

Manufacturing process

1.Material

2.Pressure welding

3.Cutting

4.Welding of ends bar

5.Hot dipped galvanizing

6.Final shipment

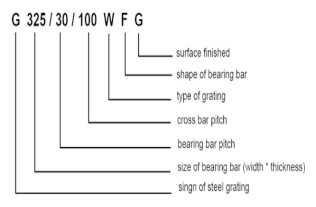

Sign of steel bar grating

Materials

Carbon steel(ASTM A36)

Stainless steel 304

Stainless steel 316

Aluminum alloy

Size

1.Bearing bar pitches may be 20, 22, 30, 32.5, 34.3, 40, 60mm, of which 30mm and 40mm are recommended.

2.Cross bar pitch may be 38, 50, 60 to 100mm, of which 50mm and 100mm are recommended.

Sign of surface treatment

1.G-Hot Dip Galvanized

(ASTM A123/A123M-09: Standard specification for zinc (hot-dip galvanized) coatings on iron and steel products

BS EN ISO 1461:1999: Hot dip galvanized coatings on fabricated iron and steel articles—Specifications and test methods)

2.P-Painted

3.U-untreated

Type of grating

1.W:Press-welded

2.L:press-locked

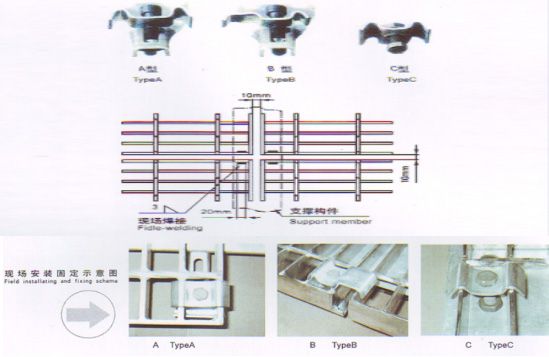

Installation of steel grating

1.Welding is advisable for those of permanent use without being removed/dismantled. Just weld it onto the support with specific location at the first piece of flat steel of each corner of the plate. Fillet weld is required with weld length not less than 20mm and height not less than 3mm. Daxing Brand Installation Clips, which will not destroy the zinc coat and be easy to remove, are available, Each ganel shall use at least four installation clips.

2.For the larger panels preferably some more clips are required to fix to the available support members. Refer to the following table when selecting installation clips:

Type A-comprising a top clip with double saddle a lower clip with teeth and a M10(or M8).

Type B-comprising a top clip with duble saddle(of which one saddle can secure the two bear bars of abjacent panels),a lower clip with teeth and a M10(or M8).

Type C-comprising a top clip with double saddle and a M10(or M8).

Type of saddle clips | Applicable grating specifications | ||

A-30 | B-30 | C-30 | Bearing bars at 30mm pitch |

A-40 | B-40 | C-40 | Bearing bars at 30mm pitch |

A-60 | B-60 | C-60 | Bearing bars at 30mm pitch |

Applications

Industrial platform

Bridge Flooring

Trench covers

Walkways

Ramps

Catwalks

MONO Group is one of Titanium alloy, Nickel alloy,Stainless steel, Aluminum alloy manufacturer&Supplier&Wholesaler from China,We can supply steel grating and Perforated sheet and other metal perforated products as per customized size.,pls contact us freely for your RFQ to info@monokj.com